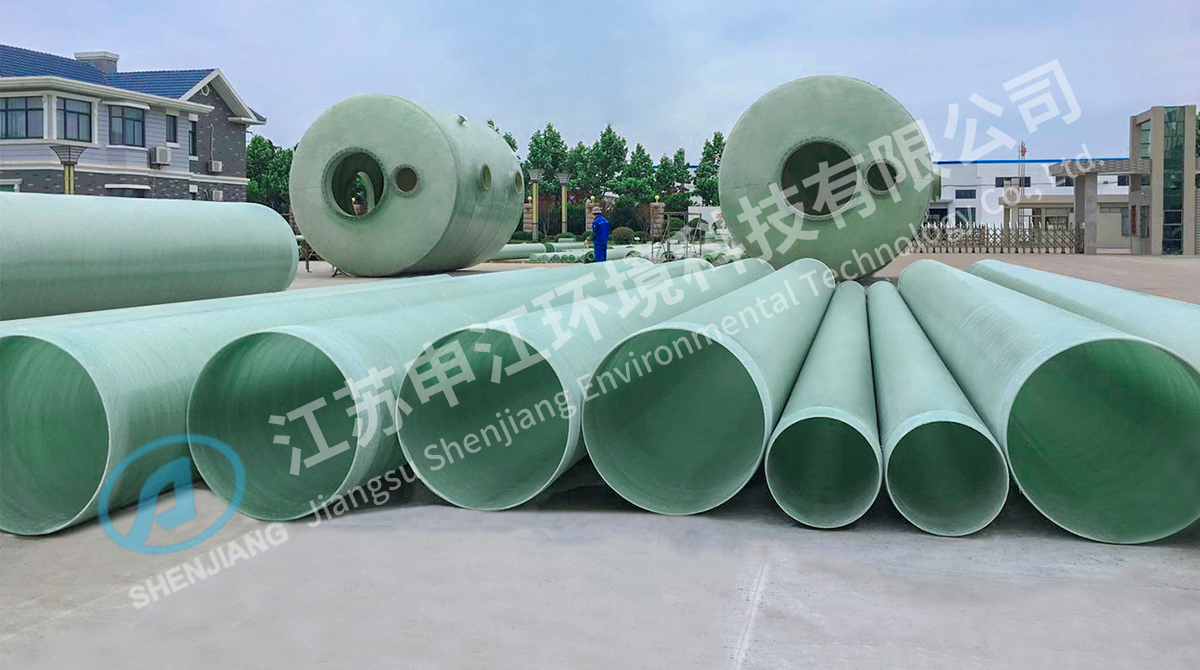

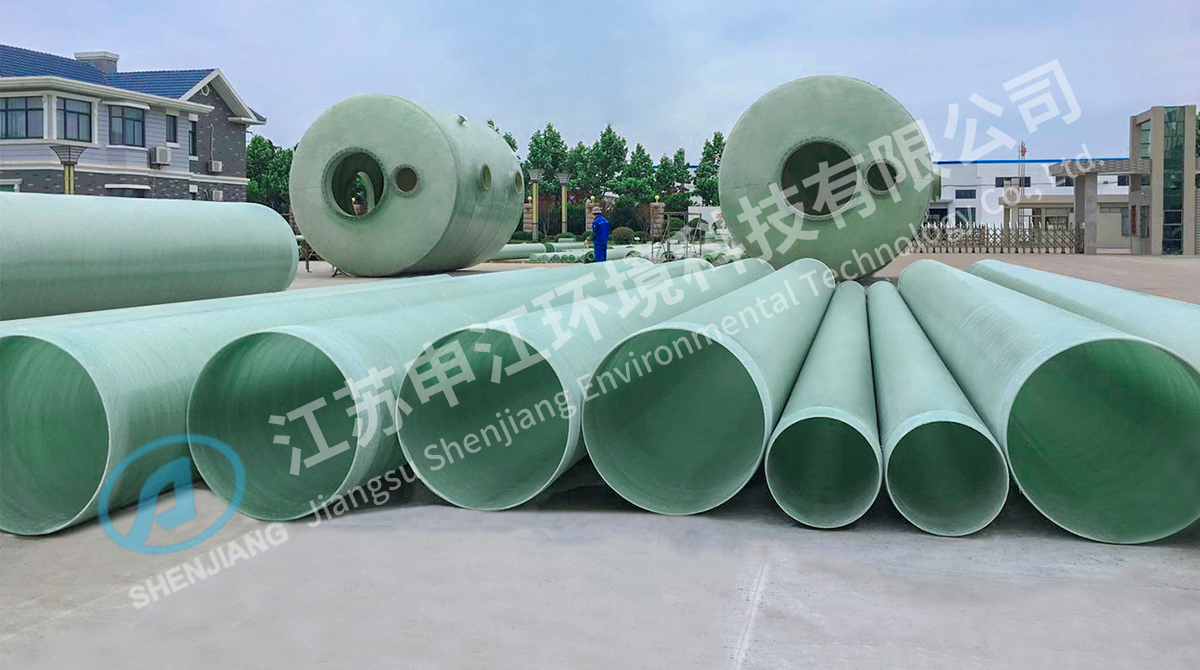

Basic Differences Between FRP Pipes and Metal Pipes

FRP pipes differ fundamentally from metal pipes in their material structure. FRP pipes are primarily composed of a composite of resin, glass fiber, and fillers. Their internal structure features a fiber-reinforced, layered design. This composite structure contributes to their light weight and superior corrosion resistance. Metal pipes, on the other hand, are primarily made of steel, cast iron, or stainless steel. While they possess high strength and pressure-bearing capacity, they are susceptible to environmental corrosion. In engineering applications, these material differences dictate distinct requirements for transportation, installation, and ongoing maintenance, impacting construction costs and ease of use.

Significant Weight Differences

FRP pipes are typically significantly lighter than metal pipes of the same diameter, thanks to their fiber composite material structure. For example, a typical FRP pipe weighs only one-fourth to one-fifth the weight of a steel pipe of the same specification. This lightweight feature not only reduces transportation costs but also reduces the need for large lifting equipment during construction. In some locations with limited working conditions, lightweight pipes can be handled and installed manually or with small machinery, greatly increasing construction flexibility. Due to its heavy weight, metal pipes often require cranes or other large equipment for handling and hoisting, increasing the complexity of construction.

Comparison of Installation Ease

FRP pipes offer significant ease of installation. Firstly, their light weight allows for handling and assembly by a small number of workers, reducing manpower. Secondly, FRP pipes offer a variety of joint types, such as socket, flange, and double O-ring connections, allowing for flexible selection based on project requirements and reducing the need for welding or cutting during installation. This not only shortens the construction period but also reduces safety risks on the construction site. In contrast, metal pipes often require welding or flange connections, which takes longer to install and requires a higher level of work environment and skilled personnel.

Construction Equipment Requirements

Due to their weight difference, FRP pipes are less dependent on equipment during construction. In most cases, installation can be completed using standard lifting machinery or manual labor, offering significant advantages in projects with limited space or complex terrain. Metal pipes, on the other hand, require large lifting and welding equipment and have higher load-bearing and operating space requirements on the construction site. In terms of project cost and construction time control, FRP pipes offer certain economic and efficiency advantages due to their reduced equipment requirements.

Construction Time and Labor Input

FRP pipes significantly shorten construction time due to their light weight and simpler joint configurations. For the same amount of work, FRP pipes are generally more efficient to install than metal pipes, which also means reduced labor input. In large-scale projects, this difference can significantly reduce labor costs and accelerate project delivery. Metal pipes, on the other hand, require a longer construction timeframe and higher labor requirements due to the cutting, welding, and anti-corrosion treatment involved.

Comparison of Different Pipe Weights and Construction Requirements

To more clearly illustrate the differences between the two, the following table provides a comparison:

| Pipe Type |

Unit Weight (DN300) |

Installation Requirements |

Dependence on Construction Equipment |

| FRP Pipe |

Approx. 30–35 kg/m |

Socket, flange, minimal machinery |

Low |

| Carbon Steel Pipe |

Approx. 120–140 kg/m |

Welding, flange, large equipment |

High |

| Stainless Steel Pipe |

Approx. 100–130 kg/m |

Welding, flange, large equipment |

High |

As the table shows, FRP pipes' advantages in weight and installation methods offer certain advantages in terms of construction equipment investment and operational flexibility.

Transportation and Storage Convenience

FRP pipes also offer flexibility in transportation and storage. Their lightweight design allows transport vehicles to carry more pipes, reducing trip times and costs. Furthermore, its corrosion resistance reduces the complexity of storage protection, whereas metal pipes require rust prevention during storage and additional protection and securing during transportation.

Long-Term Operation and Maintenance Ease

While this article primarily focuses on weight and ease of installation, these advantages also extend to long-term operation. The lightweight design means that FRP pipes are easier to dismantle and reinstall during replacement or repair, reducing operational maintenance challenges. In contrast, metal pipes, due to their greater weight and complex connection configurations, require more manpower and equipment for repair.

Different Application Scenarios

Due to their light weight and ease of installation, FRP pipes are particularly suitable for projects with complex terrain, limited construction sites, or requiring rapid construction, such as water supply in mountainous areas, seawater transportation, and temporary pipeline projects. Metal pipes are more commonly used in industrial environments with high pressure requirements or those subject to long-term mechanical shock. By selecting the right material based on the specific project requirements, both ease of construction and safety can be achieved.

English

English  中文简体

中文简体 Español

Español عربى

عربى русский

русский ไทย

ไทย bahasa Indonesia

bahasa Indonesia Tiếng Việt

Tiếng Việt