Jiangsu Shenjiang Environmental Technology Co., Ltd.

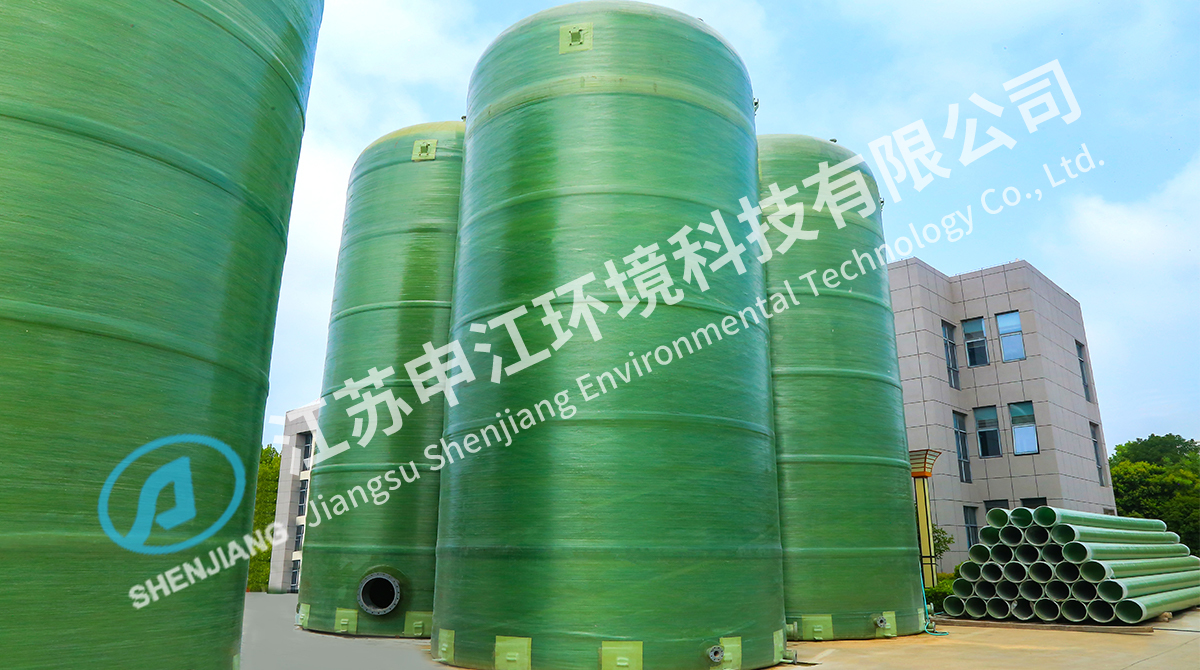

Established in 1996, Jiangsu Shenjiang Environmental Technology Co., Ltd. is a professional China FRP Vessel Manufacturers and FRP Vessel Factory.And is nestled in the picturesque city of Yancheng, Jiangsu Province, known for its moniker "Land of Water and Fish-Rice." The company specializes in designing, developing, manufacturing, and installing complete sets of waste gas treatment equipment and resin-based composite material products. Adhering to the principle of "market orientation and technological innovation," we have been steadfast in scientific and technological innovation, ensuring the company's sustained and stable growth. Our team comprises 218 dedicated employees, including 35 professional technicians, and we are equipped with over 100 advanced testing and production machines. Our R&D center spans 3,000 square meters, while our factory buildings, office buildings, and business buildings cover an area of 35,000 square meters. With a registered capital of 101.6 million yuan and total assets amounting to 154 million yuan, we have evolved over two decades through continuous self-innovation, utilizing new materials, technologies, and processes, resulting in a cluster of industries with multiple patents. Shenjiang embraces a diversified and multifaceted approach to industry-academia integration. We adopt an applied training model that combines theoretical research with practical exploration, establishing long-term cooperative relationships with esteemed institutions like Southeast University, University of Shanghai for Science and Technology, Xi'an Jiaotong University, "China Environmental Protection Equipment Industry Base Technology Research Center," and "Jiangsu Pollution Control and Resource Utilization Engineering Technology Research Center." In addition, we actively promote international scientific and technological cooperation, forging partnerships with countries such as Indonesia, Thailand, Austria, and Singapore. Guided by the business philosophy of "technology, credibility, service, and development," we have developed a range of innovative products including waste gas treatment and recovery systems, desulfurization and denitrification systems, central air conditioning unit systems and fittings, windpipes, resin-based composite pipes, water supply and drainage sandwich pipes, resin-based composite material non-standard equipment and storage tanks, cooling towers, chemical fiber non-standard equipment, cleaning furnace equipment, and painting complete sets of equipment. These new processes are characterized by advanced technology, strong adaptability, simple operation, and low costs. We have filed 40 proprietary technology certifications, with 30 utility granted, 4 inventions, and 7 PCT certificates. Our independently developed waste gas recovery and treatment devices have been listed in the "Jiangsu Province Key Promoted New Technology and New Product Catalog." With a global presence, we have established supply, installation, and sales offices in various locations, including Indonesia, Singapore, Austria, Xinjiang, Fujian, Nanjing, Shandong, and Sichuan. Moreover, we boast professional construction teams specializing in environmental protection, mechanical and electrical, and anti-corrosion and insulation equipment installation. As our enterprise grows, Shenjiang is committed to enhancing its brand influence, rallying together to face challenges, and seeking mutual development for a shared future. We adhere to a people-oriented approach and a development philosophy that emphasizes scientific innovation. With a united front and the determination to overcome difficulties, we maintain our entrepreneurial spirit and unwavering commitment to our founding principles. We strive to create intellectual property for our enterprise, gradually shift focus to our core business, and pursue diversified development. We are constantly upgrading and transforming, targeting the development trends of both domestic and international markets, and aiming to establish new projects and achieve new outcomes. We are dedicated to making a greater contribution to the cause of environmental protection.

English

English  中文简体

中文简体 Español

Español عربى

عربى русский

русский ไทย

ไทย bahasa Indonesia

bahasa Indonesia Tiếng Việt

Tiếng Việt