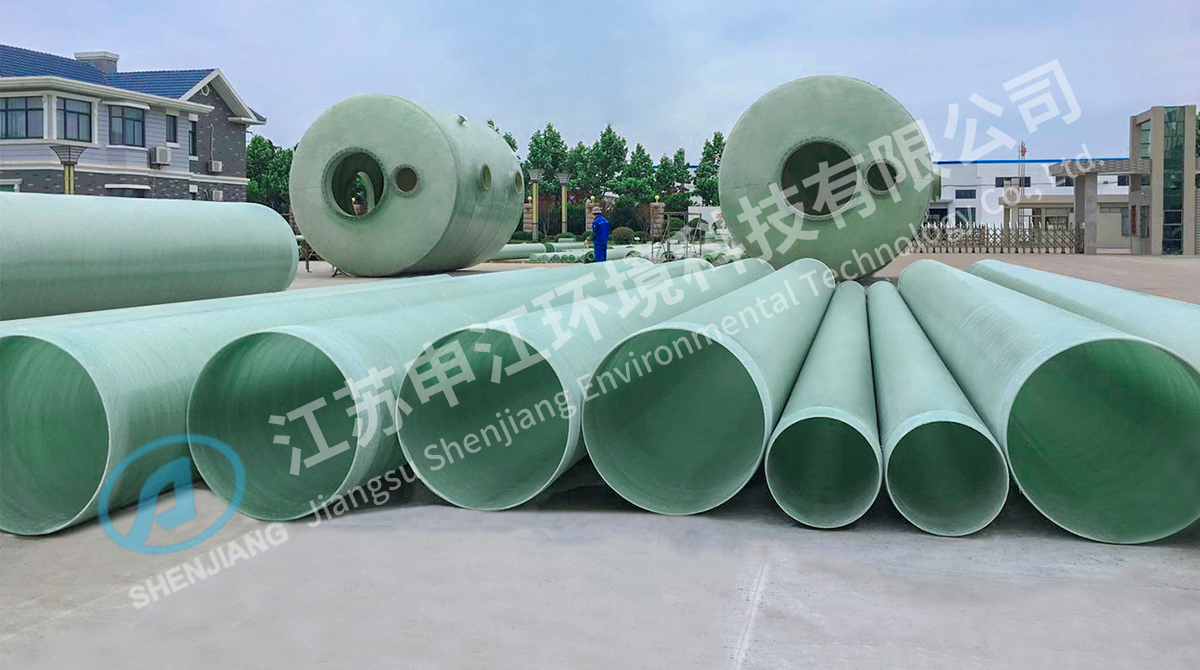

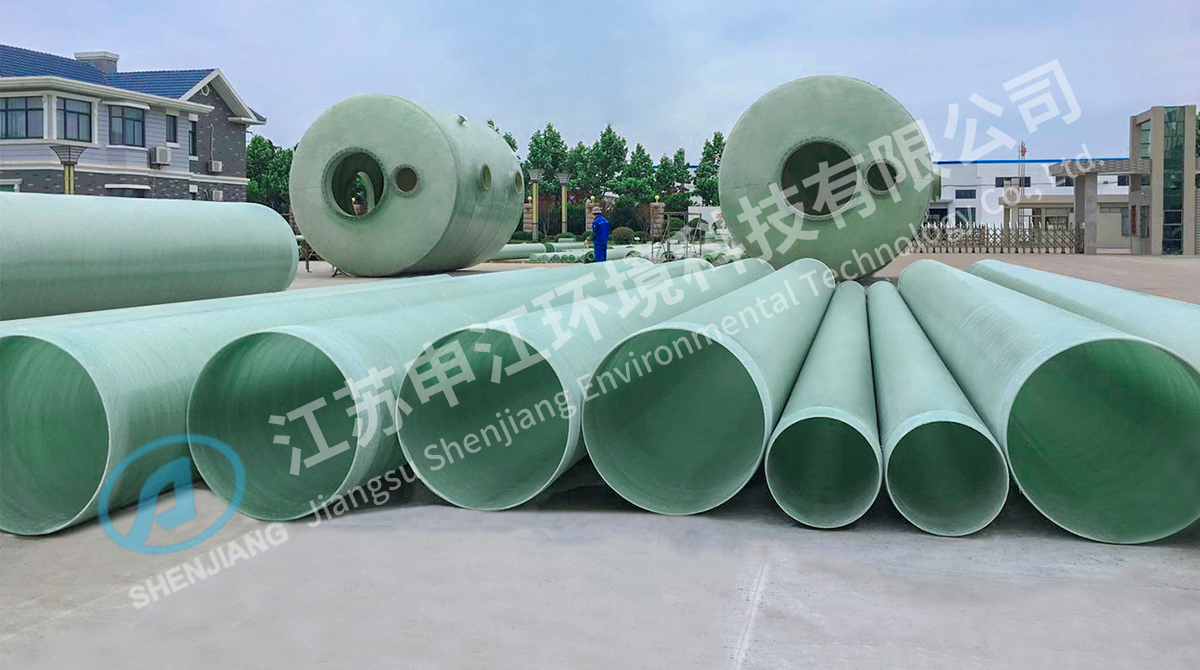

Basic Concepts of FRP Pipes and Fittings

FRP pipes are a type of pipe made of a composite material of glass fiber and resin. It uses glass fiber as a reinforcing material and combines it with resin to form a solid pipe structure. FRP pipes are widely used in chemical, petroleum, electric power, sewage treatment, construction, agricultural irrigation and other fields due to their light weight, corrosion resistance and high strength.

The production process of FRP pipes usually includes the laying of glass fiber fabrics, the impregnation and curing of resins, and finally forms a composite pipe with high strength and low density. fittings usually include flanges, tees, elbows, joints, etc., which are mainly used for pipe connection, diversion or diversion.

Main Features of FRP Pipes

Lightweight and High Strength

One of the biggest features of FRP pipes is their lightness. Compared with traditional metal pipes, FRP pipes have a lower density, usually 1/4 to 1/3 of steel pipes, so they are easier to install and carry. Despite its light weight, FRP pipes are very strong and can withstand large internal pressures and external loads, making them suitable for high-pressure and complex pipe systems.

Corrosion resistance

Another major advantage of FRP pipes is corrosion resistance. Since FRP pipes are made of a composite of resin and glass fiber, these materials themselves have strong chemical corrosion resistance and can resist the erosion of most acid, alkali, and salt chemicals. Therefore, FRP pipes perform particularly well in highly corrosive environments such as chemical industry, sewage treatment, and seawater transportation. They are not easy to rust or damage, and can greatly extend their service life.

High temperature resistance

FRP pipes usually have good high temperature resistance. The type and quality of resin have an important influence on the high temperature resistance of the pipe. Common FRP pipes can withstand temperatures between 70°C and 120°C. With the application of certain special resins, the temperature resistance can reach a higher level. Therefore, FRP pipes can be widely used in some occasions that require high temperature treatment (such as hot water transportation, steam pipes, etc.).

Good electrical insulation

FRP pipes also have good electrical insulation properties. Due to the insulating properties of its materials, it is widely used in power facilities, especially in power transmission and distribution systems, which can avoid current leakage or short circuits and ensure the safety of facilities.

Wear resistance

FRP pipes also have a certain wear resistance, especially when conveying particulate matter or fluids containing particulate matter (such as sewage, slurry, etc.), FRP pipes can effectively reduce friction and wear, and ensure the long-term stable operation of the pipe.

Low thermal expansion coefficient

FRP pipes have a low thermal expansion coefficient, which means that they expand or contract less when the temperature changes. This feature makes FRP pipes more stable in environments with large temperature differences, and it is not easy to cause pipe deformation or damage due to thermal expansion and contraction.

Excellent processing performance

FRP pipes have good processing performance and can be customized according to actual needs. For example, pipes can be made into different diameters, lengths and wall thicknesses according to project requirements to adapt to various fluid conveying and use environments. Moreover, FRP pipes can be further processed into various complex fittings (such as elbows, tees, flanges, etc.) through heat treatment, compression molding and other technologies.

Environmental protection

The environmental protection characteristics of FRP pipes are gradually recognized by more and more industries. Compared with traditional metal pipes, FRP pipes do not produce harmful substances during production and use, and due to their strong corrosion resistance, they reduce pollution to the environment. In addition, FRP pipes have high recyclability and can be recycled and reused after their service life, which meets modern environmental protection requirements.

Easy installation

The installation of FRP pipes is relatively simple. Due to its light weight, it can reduce labor intensity and installation time. In addition, FRP pipes can be connected in a variety of ways such as bonding, threaded connection, flange connection, etc., which are convenient and flexible to install and have strong adaptability.

Application areas of FRP pipes and fittings

Due to their excellent performance, FRP pipes and fittings have been widely used in many industries. The following are several typical application areas:

Chemical industry

The chemical industry is one of the most widely used areas for FRP pipes. Since chemical production often requires the transportation of highly corrosive chemicals (such as acids, alkalis, and salts), FRP pipes can provide excellent corrosion resistance to ensure the safe transportation of chemicals.

Oil and gas industry

In the oil and gas industry, FRP pipes are widely used to transport liquids and gases such as oil and natural gas. Its corrosion resistance and high compressive strength make it suitable for use in various complex geological environments.

Environmental protection and water treatment

In sewage treatment and water treatment, FRP pipes are often used to transport liquids containing corrosive and particulate matter. Its corrosion resistance and wear resistance make FRP pipes have irreplaceable advantages in environmental protection projects.

Power industry

FRP pipes are widely used in power facilities due to their excellent electrical insulation, especially in the protection and transmission system of power cables. It can avoid current leakage and improve the safety of the power system.

Agricultural irrigation

In agricultural irrigation systems, FRP pipes are widely used for the transportation of agricultural water due to their corrosion resistance and aging resistance. It can improve the utilization efficiency of water resources and extend the service life of irrigation systems.

English

English  中文简体

中文简体 Español

Español عربى

عربى русский

русский ไทย

ไทย bahasa Indonesia

bahasa Indonesia Tiếng Việt

Tiếng Việt