Scope of application and common uses of FRP tanks

Liquid storage in industrial production

FRP tanks are widely used in industrial liquid storage, mainly because they have a certain tolerance to a variety of chemical liquids and are suitable for liquid storage tanks under various working conditions. In chemical plants, FRP tanks are usually used to store corrosive liquids such as hydrochloric acid, sulfuric acid, sodium hypochlorite, and sodium hydroxide. Since traditional metal materials are easily corroded by these chemical media, the use of FRP tanks helps to reduce the maintenance frequency and equipment replacement cycle, and improve the continuity and stability of production. FRP tanks are also suitable for the storage of neutral or weakly alkaline liquids, such as industrial wastewater and neutralization liquid. During the liquid treatment process, FRP tanks can maintain their structural integrity and reduce the environmental impact caused by leakage.

Application in water treatment

In water treatment systems such as urban water supply, sewage treatment, and industrial wastewater treatment, FRP tanks are mainly used for raw water storage, reaction liquid storage tanks, neutralization tanks, and precipitation liquid storage tanks. In reverse osmosis systems and softening water treatment devices, FRP tanks are often used as pressure vessels (such as resin tanks, sand filter tanks, etc.). It has strong adaptability to water quality and will not release impurities or pollutants. It is suitable for application environments with high water quality requirements. Since FRP materials are not easy to scale or rust, the frequency of cleaning can be reduced in long-term operation, reducing the cost of equipment operation and maintenance.

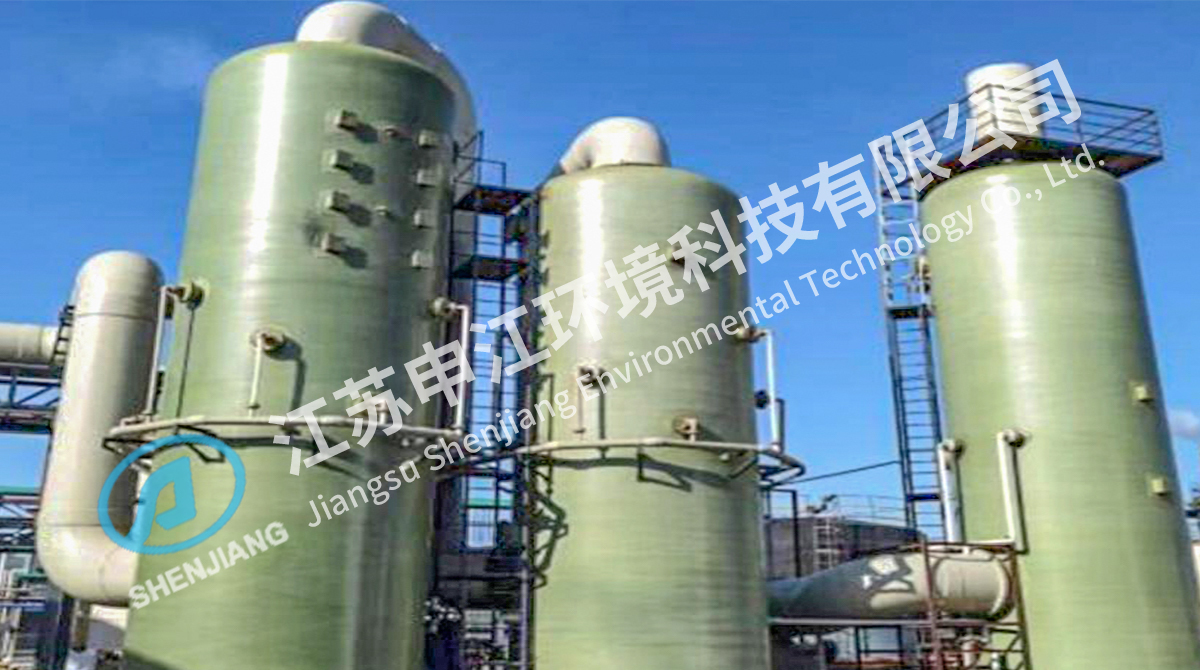

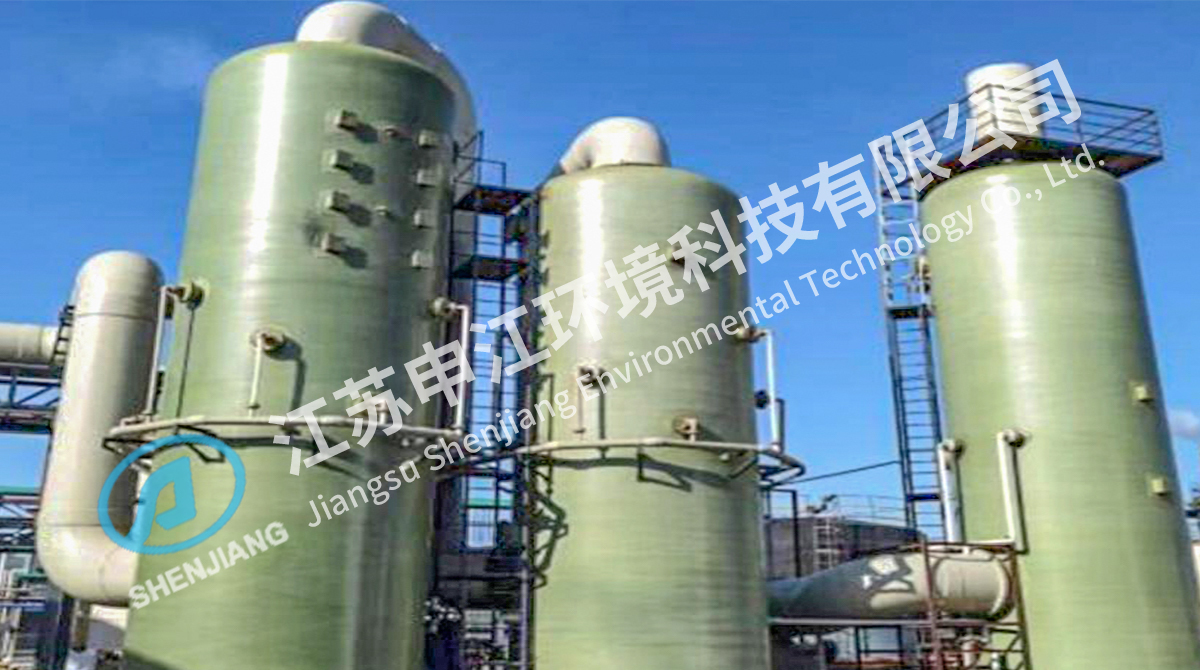

Usage scenarios in the environmental protection industry

With the improvement of environmental protection requirements, more and more industrial projects need to build supporting wastewater and waste gas treatment systems. FRP tanks have certain adaptability in environmental protection equipment due to their material characteristics. In terms of waste gas treatment, FRP tanks are often used as liquid storage tanks for washing towers and neutralization towers to store acid-base neutralizers, absorption liquids, etc. In wastewater treatment, they are used for intermediate buffering, reaction regulation, sludge storage and other links. Especially in the treatment process involving highly corrosive gases or liquids, the anti-corrosion ability of FRP tanks makes it one of the common options.

Auxiliary use in the food and beverage industry

In the food processing industry, some process links require containers made of non-metallic materials to avoid reaction with the medium. FRP tanks have certain applicability in such scenarios, especially in raw material pretreatment, food additive preparation, cleaning agent storage and other links. For example, some dairy factories use FRP tanks to store liquid alkali or pickling agent for cleaning equipment pipes. In addition, FRP tanks are sometimes used as temporary storage containers in juice production and beverage preparation. Due to the strict requirements of the food industry on sanitary conditions, when using FRP tanks, it is necessary to ensure that its lining material meets the relevant standards to avoid migration pollution.

Application in agricultural and rural facilities

In agricultural irrigation systems, FRP tanks can be used as liquid storage tanks in water and fertilizer integrated equipment to store fertilizer solutions or pesticide dilutions. It is easy to transport, easy to install, and has strong corrosion resistance, which is suitable for use in rural areas or areas with limited conditions. In rural drinking water projects, FRP tanks can be used as clean water storage tanks, especially for mountainous projects with complex terrain or difficult construction.

Production auxiliary equipment in the chemical and pharmaceutical industries

In the chemical industry, FRP tanks are not only used for the storage of conventional liquids, but are also often used as reaction tanks, blending tanks and buffer tanks to complete the temporary storage and mixing of materials before and after chemical reactions. In pharmaceutical companies, especially in the production of intermediates, corrosive solutions are often used. FRP tanks are more practical in these scenarios due to their chemical corrosion resistance. Although some pharmaceutical occasions have higher requirements for equipment cleanliness and material stability, FRP tanks still play auxiliary functions in non-critical process sections to improve the adaptability of the overall system.

Auxiliary use in the petroleum and energy industry

In the process of oil extraction, oil transportation and refining, some links require the storage and addition of water treatment agents, desulfurizers, corrosion inhibitors, etc. FRP tanks have certain advantages in use in environments such as oil fields and drilling platforms due to their light weight and convenient transportation. Some desulfurization and denitrification systems in the power industry also use FRP tanks to store liquids such as lime slurry, sulfuric acid, and ammonia water, as chemical reserve units to participate in environmental protection treatment processes.

Scenarios for anti-corrosion requirements in marine and port facilities

In offshore environments or coastal ports, metal containers are prone to rust due to the high salt concentration in the air. The non-metallic properties of FRP tanks make them suitable for such high-salt and high-humidity environments, and are often used to store fresh water, diesel, cleaning agents and other materials. Flushing systems, clean water supply systems, cooling systems, etc. in port equipment can also use FRP tanks to meet the storage and allocation needs of liquids.

Small tanks in experimental devices and educational purposes

In laboratories of universities and scientific research institutions, FRP tanks are often used as teaching equipment or experimental containers to simulate corrosion, chemical reactions, environmental adaptation and other test items. Small FRP tanks are easy to carry and operate, and can be customized according to experimental requirements, becoming one of the important components in experimental devices.

Application extension in special customized scenarios

In addition to standard uses, FRP tanks can also be designed and manufactured in a non-standard manner according to the specific needs of users. For example, some companies customize FRP tanks as mobile liquid storage units for vehicle transportation; some units also make them into double-layer structures to improve insulation or leakage prevention capabilities. In professional fields such as military, aviation, and shipping, fiberglass tanks are also used as auxiliary equipment, such as for emergency water supply, temporary chemical storage, and other tasks.

What is the difference between FRP tanks and traditional tank materials?

Basic differences in material composition

The core difference between different tanks is first reflected in their material composition. FRP tanks are composite tanks composed of glass fiber and resin, while traditional tanks are mostly made of a single material, such as metal or cement. Different types of materials determine the basic characteristics of the tank in terms of physical properties and chemical stability.

FRP tanks use glass fiber as a reinforcing skeleton and epoxy resin, unsaturated polyester resin, etc. as a matrix, and are formed by mechanical winding or compression molding. Traditional tanks are divided into three categories: carbon steel tanks, stainless steel tanks and cement tanks. Carbon steel tanks are welded with ordinary steel plates; stainless steel tanks are made of stainless steel materials such as 304 and 316L; cement tanks are made of reinforced concrete structures and are usually larger in size. The difference in material composition lays the foundation for the difference in their respective performance.

Comparison of quality and transportation and installation

The dead weight of the tank has a direct impact on the transportation method, installation conditions and construction progress. FRP tanks have a lower material density and are significantly lighter than traditional metal or concrete tanks. They are more flexible in transportation and hoisting, and are convenient for use in environments with complex terrain or limited space.

The relative density of FRP tanks is generally 1.5~2.0, which is only about a quarter of that of steel, which can greatly reduce the load on equipment; traditional carbon steel and stainless steel tanks are heavier and require the use of heavy equipment such as cranes; cement tanks have a heavy structure and can only be cast in situ on site, and are almost impossible to transport. Therefore, from the perspective of construction convenience, FRP tanks have more operating space.

Differences in corrosion resistance

The corrosion resistance of the tank body directly affects its applicability and service life under complex working conditions. Due to its composite material structure, FRP tanks have strong resistance to a variety of acids, alkalis and organic solvents, and are suitable for a variety of corrosive media.

In industries such as chemical, environmental protection and sewage treatment, FRP tanks are often used to store corrosive liquids such as hydrochloric acid, sulfuric acid, and sodium hydroxide. In contrast, carbon steel tanks are prone to rust if they are not treated with internal anti-corrosion; although stainless steel tanks have certain anti-corrosion capabilities, they still have corrosion risks in chlorine-containing environments or strong acid environments; cement tanks are mainly subject to alkaline corrosion and have limited resistance to acid erosion. Therefore, FRP tanks are more suitable for applications with diverse corrosive media.

Cost structure and budget distribution

The cost structure of tanks of different materials in the manufacturing, transportation, installation and maintenance links is different. The overall manufacturing cost of FRP tanks is medium, but the transportation and maintenance costs are relatively low, which has a certain economy.

Carbon steel tanks have low initial manufacturing costs, but they require regular anti-corrosion treatment, which increases operation and maintenance expenses; stainless steel tanks have high overall procurement costs due to the high price of materials; although cement tanks have cheap raw materials, they have a long construction period and high labor and site costs. Overall, FRP tanks have the advantage of cost balance in small and medium-sized projects, while traditional tanks may be more cost-effective in large-capacity or high-pressure scenarios.

Differences between service life and maintenance cycle

Whether the storage tank is durable during use and whether it needs frequent maintenance is one of the core factors in evaluating the long-term use value of equipment. FRP tanks usually have a service life of 15 to 25 years due to their stable structure and low corrosion resistance, and the maintenance work is relatively simple.

In contrast, carbon steel tanks require regular rust removal and repainting, and the maintenance frequency is high; although stainless steel tanks have good corrosion resistance, welds and joints still need to be checked regularly; cement tanks may crack due to climate or structural stress, requiring grouting or surface repair. Therefore, from the perspective of later operation and maintenance, the overall maintenance burden of FRP tanks is relatively low.

Pressure bearing capacity and restrictions on operating conditions

The pressure bearing capacity of a storage tank determines whether it can be used for pressurized transportation or storage of pressurized media. Traditional metal tanks have certain advantages in pressure bearing performance and are suitable for high-pressure systems or reaction systems, while FRP tanks are usually used in normal pressure or low-pressure environments.

Although FRP tanks can improve their structural strength through reasonable winding processes, they are generally not used for high-pressure liquid or gas storage. Carbon steel and stainless steel tanks are often used in high-pressure boiler water tanks, reactor systems and other occasions, and have a higher structural safety factor. Cement tanks are almost only used for normal pressure storage. Therefore, metal tanks are more suitable under specific pressure requirements.

Flexibility of processing and customization

Modern projects often have non-standard customization requirements for the functionality, volume, interface structure and other aspects of storage tanks. FRP tanks can be flexibly customized according to user requirements, including shape, caliber, number of layers, lining structure and other aspects, due to the use of mold forming and winding manufacturing processes.

Traditional tanks perform differently in this regard. Although metal tanks also support customization, the processing difficulty is high for designs such as special-shaped structures and internal and external composite layers, and the welding process requirements are strict; cement tanks basically only support regular geometric shapes and have limited customization capabilities. Therefore, for occasions with high design complexity, FRP tanks have certain adaptability.

Safety of use and risk control methods

The tank body involves multiple aspects such as electrical safety, explosion risk, and leakage control during use, and the safety performance of different materials varies. FRP tanks are non-conductive materials and are relatively safe in terms of static electricity accumulation and spark induction. They are suitable for places with fire and explosion requirements.

When carbon steel and stainless steel tanks are used in flammable gases or explosive environments, lightning protection grounding, anti-static and other supporting treatments are required. Although cement tanks have no conductive risks, the structure is prone to leakage after being damp or cracked. Therefore, from the perspective of safety control, FRP tanks have certain advantages in low-pressure safety occasions.

Differences in environmental adaptability

The weather resistance of the tank body under outdoor or harsh climatic conditions will directly affect its structural stability and service life. FRP tanks can maintain a relatively stable state in a humid, high-salt, and ultraviolet-strong environment, and are not prone to material aging or structural damage.

Traditional carbon steel tanks are prone to oxidation and rust in high-humidity environments; although stainless steel tanks have a protective film on the surface, they still have corrosion risks in high-salt areas such as the seaside; cement tanks may cause structural cracking or peeling due to rainwater penetration. Therefore, FRP tanks are more applicable in high-humidity, acid rain or salt fog areas.

Differences in adaptability of application scenarios

FRP tanks and traditional tanks are each suitable for different industry scenarios. FRP tanks are mainly used in water treatment, chemical liquid storage, environmental protection equipment, agricultural irrigation, domestic water supply and other medium and low pressure and corrosion resistance requirements.

Carbon steel tanks are suitable for neutral media such as conventional water storage, fire fighting, and oil; stainless steel tanks are mostly used in food, beverages, pharmaceuticals and other fields with high hygiene requirements; cement tanks are often used for large-volume dry powder storage, such as cement, mineral powder, and grain. Therefore, different tank materials need to be reasonably matched according to industry attributes and medium characteristics.

What are the factors that affect the service life of FRP tanks?

Quality of raw material selection

The performance of FRP tanks depends largely on the raw materials used, including the type of resin, the type of glass fiber and its content ratio. Whether the material selection is reasonable and whether it conforms to the characteristics of the storage medium will directly affect the stability and durability of the tank structure.

Common types of resins include epoxy resin, unsaturated polyester resin, vinyl resin, etc. Different types of resins have their own characteristics in terms of chemical corrosion resistance, temperature resistance and mechanical strength. If the material selection is inappropriate, such as using ordinary unsaturated resin in a strong acid medium, it is easy to cause premature aging of the inner wall of the tank. Glass fiber, as a reinforcing material, affects the strength and rigidity of the tank. Insufficient content or unreasonable arrangement may reduce the structural bearing capacity. During the design and manufacturing stage, the raw materials must be reasonably selected according to the specific medium, working temperature, pressure level and other parameters to avoid shortening the equipment life due to material mismatch.

The degree of standardization of the production process

The molding method of FRP tanks usually adopts mechanical winding or manual laying. Whether the process is standardized has a direct impact on the strength and density of the tank structure. Factors such as winding angle, thickness control, resin impregnation degree, and curing time will affect the overall performance of the tank.

If the winding speed is uneven, the fiber arrangement is disordered, or the resin and fiber are not fully bonded during the production process, local voids or stress concentration may occur. These hidden dangers may not be obvious in the early stage of use, but they are prone to cracking, leakage and other problems in long-term operation. In addition, if the temperature is improperly controlled or the time is insufficient during the curing process, the physical strength and chemical resistance of the resin will also be reduced. Manufacturers should adopt standardized process flows, implement quality control specifications, and adapt the process according to the type of storage tank to ensure the structural reliability of FRP tanks.

Types and concentrations of storage media

FRP tanks are mainly used to store various types of liquid or gaseous media. Different media have different degrees of chemical reaction to the tank material, which is an important factor in determining its aging speed and service life.

Acidic media such as sulfuric acid and hydrochloric acid will gradually corrode the resin, especially under high concentration conditions, the corrosion rate is faster. Alkaline media such as sodium hydroxide have little effect on some resins, but may also cause the molecular structure of the resin to degenerate. Solvent media such as methanol and acetone may penetrate the resin, causing the inner wall to soften or swell. If impurities, particles or high-temperature steam are mixed into the medium, it will also accelerate the wear of the tank or material degradation. Therefore, when designing FRP tanks, the characteristics of the storage medium must be fully evaluated, and the lining and protective layer materials must be reasonably configured in combination with its concentration, temperature, pressure and other parameters.

Common Storage Media and Their Effects on FRP Materials

|

Storage Medium

|

Characteristics

|

Potential Impact on FRP Materials

|

|

Dilute Sulfuric Acid

|

Strongly acidic

|

Prolonged exposure may gradually corrode inner lining

|

|

Sodium Hydroxide

|

Strongly alkaline

|

Less impact on some resins, but high concentration requires special design

|

|

Saltwater/Seawater

|

Electrolyte-containing solution

|

Causes slow corrosion, needs anti-permeation treatment

|

|

Alcohol/Acetone

|

Organic solvents

|

Strong permeability, may cause resin layer swelling or softening

|

Working temperature and ambient temperature difference

The ambient temperature of the FRP tank has a great influence on its structural stability and material aging rate. Especially in areas with large temperature differences, the tank material will produce tiny cracks due to thermal expansion and contraction, and long-term accumulation may lead to structural degradation.

Most FRP materials are suitable for the conventional temperature range of -40℃ to 80℃, but if the temperature exceeds its heat resistance limit for a long time, the resin will soften, deform or decompose. In low-temperature environments, materials may crack brittlely, especially in winter, if the medium in the tank freezes, it will cause the tank to expand and damage.

Areas with large temperature differences between day and night or frequent seasons will also cause the tank structure to undergo repeated stress changes. Therefore, in practical applications, FRP tanks should be avoided from being used in places with high temperature, high cold or drastic temperature changes. If necessary, the external environment can be improved by adding an insulation layer or setting a sunshade.

Influence of ultraviolet rays and climatic conditions

For FRP tanks exposed to strong sunlight for a long time, the surface resin is susceptible to ultraviolet radiation and gradually ages, showing phenomena such as surface fading, powdering, and cracking, which in turn affects the overall structural performance.

Especially in tropical, coastal, and plateau areas with strong sunlight, ultraviolet radiation accelerates the breakage of resin molecular chains, causing the surface to lose its original protective effect. At the same time, climatic conditions such as wind, sand, rain, snow, and humidity will also affect the appearance and service life of the tank. For example, areas with high humidity or frequent acid rain will accelerate the local corrosion process.

For FRP tanks used outdoors, it is recommended to add a weather-resistant layer or surface coating to slow down the impact of the external climate on the tank. Regular inspection and cleaning of the tank surface will also help extend the service life.

Impact of Different Environmental Conditions on FRP Tank Service Life

|

Environmental Factor

|

Common Conditions

|

Possible Impact

|

|

Ultraviolet Radiation

|

Strong outdoor sunlight, unshaded

|

Accelerates resin surface aging, causes chalking

|

|

High Humidity or Acid Rain

|

Rainy southern regions, coastal cities

|

Leads to surface micro-cracks, promotes localized corrosion

|

|

Large Temperature Variation

|

Deserts, plateaus, areas with big day-night temperature difference

|

Causes thermal expansion and contraction, stress accumulation leading to cracks

|

|

Freezing Environment

|

Sub-zero climates or frozen tank contents

|

Causes tank wall expansion or cracking, especially without insulation

|

Installation method and basic conditions

If the FRP tank is not installed according to the specifications, the foundation structure is not firm, the pipe mouth stress is uneven or the anchoring is improper, local stress concentration may occur during operation, which may cause structural deformation or cracking.

For example, if the foundation is uneven, the tank body will cause uneven pressure on the side wall due to the center of gravity offset during long-term operation, and the bottom structure may deform; if there is no flexible connection device when the inlet and outlet are connected to the pipeline, the stress generated by the equipment during thermal expansion and contraction will be concentrated on the interface, causing local damage.

The installation of FRP tanks must be carried out strictly in accordance with the design drawings to ensure that the foundation is stable, the anchoring is firm, and the interfaces are flexible. If necessary, a buffer support structure should be installed to reduce dynamic impact.

Daily operation management method

The actual service life of FRP tanks is also closely related to their daily operation management. Including feeding speed, pressure fluctuations in the tank, switching frequency, liquid level control, etc., may have an indirect impact on the tank body.

Too fast feeding may cause severe impact and damage the lining structure; improper liquid level control may cause long-term dry-wet alternation of the tank wall, causing resin aging; frequent start-stop operation or abnormal operation (such as overpressure, overtemperature) may also accelerate fatigue damage.

It is necessary to formulate clear operating specifications and inspection systems, control equipment operating parameters, prevent overload operation, and pay attention to pressure release, temperature regulation and liquid level stability during operation to keep the equipment operating within a reasonable range of operating conditions.

Maintenance frequency and inspection measures

Although FRP tanks have lower maintenance requirements to a certain extent, this does not mean that maintenance work can be ignored for a long time. Regular appearance inspection, leakage detection, wall thickness measurement and other basic maintenance can help to find early defects and deal with them in time.

Especially for tanks used in corrosive media or exposed environments for a long time, regular maintenance cycles should be set according to the actual operating time. If surface peeling, cracks, interface leakage and other phenomena are found, local repairs should be carried out in time to avoid damage expansion.

During maintenance, avoid using metal tools to directly hit the tank wall to prevent local damage; for replacement of seals, flange gaskets and other parts, products that match the raw materials should be used to prevent chemical reactions caused by material incompatibility.

External load and stress influence

Under certain working conditions, FRP tanks may be subjected to additional stresses such as wind pressure, snow load, equipment vibration or foundation settlement from the outside, which may also affect the structural stability and service life of the tank under long-term action.

For example, in coastal areas or typhoon-prone areas, strong winds will have a lateral impact on the tank. If the anchor is not firm, it may cause overall tilting or interface tearing. In northern regions, there is more snow in winter, and the increase in top load may cause local deflection. If the vibration of nearby equipment is not treated with shock absorption, it may also be transmitted to the tank, causing fatigue damage. In the design and installation stage, it is necessary to fully evaluate the load type and intensity of the environment, and take corresponding reinforcement, shock absorption or load dispersion measures to improve the anti-disturbance ability of the tank.

Service life and renewal strategy

Even under reasonable use conditions, FRP tanks will experience natural aging and performance degradation. When the service life is reached or irreparable damage occurs, timely replacement of equipment is an important measure to ensure safe operation.

The design life of FRP tanks is about 15 to 25 years. The actual replacement cycle depends on the corrosiveness of the storage medium, the stability of the operating conditions, and the maintenance. If it is in harsh conditions for a long time, the life may be shortened to less than 10 years; if it is properly managed, it can also be extended to about 30 years.

A usage record file should be established during use, including operating data, maintenance records, and the number of overhauls, to evaluate the aging of the equipment, and a scientific replacement plan should be formulated based on industry experience to avoid safety accidents caused by aging failure.

English

English  中文简体

中文简体 Español

Español عربى

عربى русский

русский ไทย

ไทย bahasa Indonesia

bahasa Indonesia Tiếng Việt

Tiếng Việt