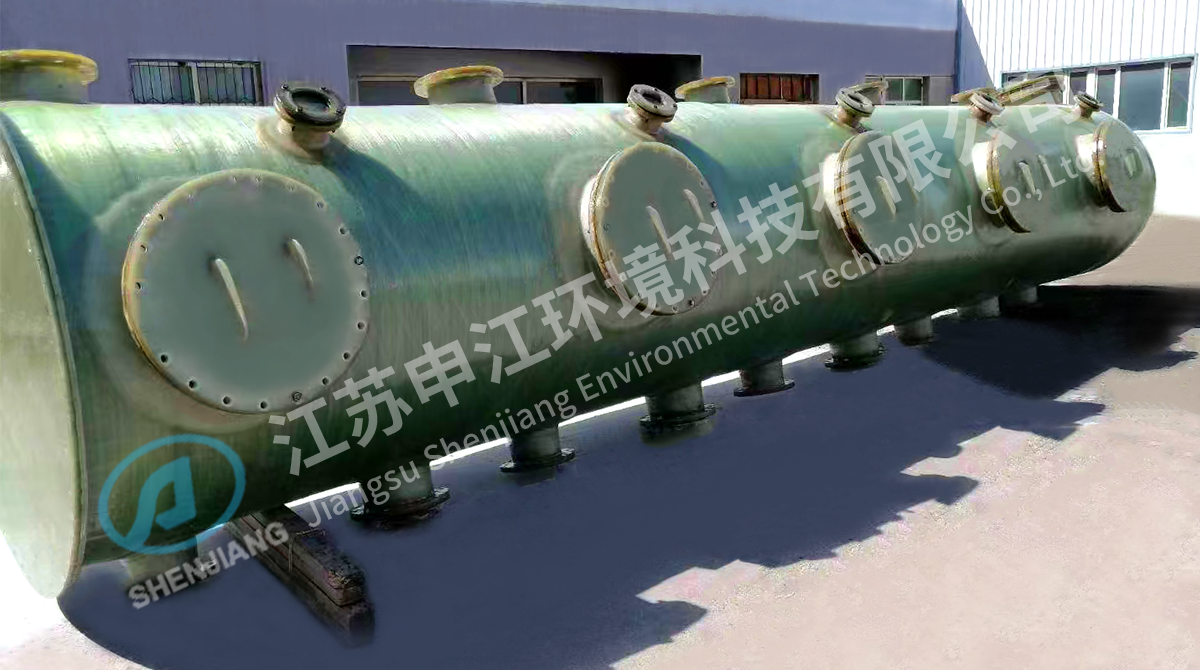

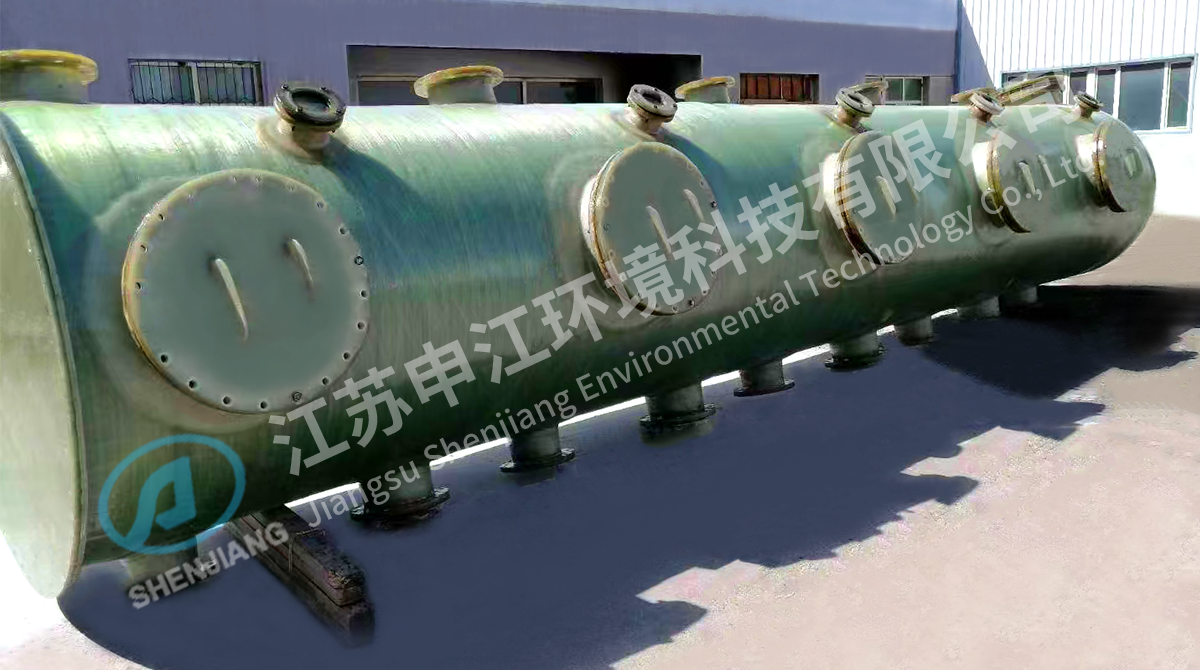

How to evaluate the long-term operation safety of FRP tanks?

Structural integrity inspection

The first step in evaluating the long-term safety of FRP tanks is to check the integrity of the tank structure. FRP tanks are mainly composed of resin matrix and reinforcement materials. The tank structure may be damaged due to chemical corrosion, mechanical stress and environmental factors during long-term use.

The integrity inspection includes two parts: visual inspection and non-destructive testing. Visual inspection mainly observes whether there are cracks, deformation, delamination or blistering on the surface of the tank. Non-destructive testing technologies such as ultrasonic testing, radiographic testing and infrared thermal imaging can more deeply discover possible defects inside the tank. Through regular structural inspections, potential hidden dangers can be discovered in time to prevent the tank from failing as a whole due to local damage.

Material performance testing

The material properties of FRP tanks directly affect their corrosion resistance and mechanical strength. When evaluating the long-term operation safety, the performance of the resin and fiber materials used in the tank should be tested. Common test contents include the chemical stability and heat resistance of the resin and the tensile strength and bonding properties of the glass fiber. Through sampling and laboratory testing, it can be understood whether the material has aged, become brittle or degraded due to long-term exposure to the working environment. These data help determine whether the tank can still maintain the expected performance standards and decide whether it needs to be replaced or maintained.

Environmental Factor Assessment

The operating environment of the FRP tank has a significant impact on its life and safety. Environmental factors include temperature changes, humidity, ultraviolet radiation, the nature of the chemical medium and its concentration. Sharp temperature fluctuations may cause the material to expand and contract, resulting in stress concentration, which in turn causes cracks. High humidity environments are prone to condensation of surface water vapor, affecting the insulation and corrosion resistance of the tank. Long-term ultraviolet radiation will accelerate the aging of the resin surface. The corrosiveness and reaction activity of the chemical medium are also key evaluation points. It is necessary to confirm that the medium and material in the environment where the tank is located match to avoid accelerated damage due to chemical reactions.

Operation Data Monitoring

In long-term operation, continuous monitoring of the operating status of the tank can detect abnormalities in time and ensure safety. Monitoring content includes internal pressure, temperature, liquid level changes and tank deformation. Installing online sensors and data acquisition systems can achieve real-time monitoring and issue alarm signals in time. Data analysis can also be used for trend prediction, discover the laws and potential risks of equipment aging, and provide a scientific basis for maintenance and replacement.

Analysis of maintenance and overhaul records

Systematic maintenance and overhaul records are important data for evaluating the long-term safety of FRP tanks. By analyzing historical maintenance records, we can understand the common fault types, frequencies and treatment effects of tanks. This information helps to judge the stability of equipment operation and the effectiveness of maintenance work. For recurring problems, we should focus on investigation and adjust the maintenance plan or improve the design if necessary.

Emergency plan and safety management

Safety assessment not only focuses on the equipment itself, but also includes the degree of perfection of the safety management system. The formulation and exercise of emergency plans are the key to ensuring timely response to emergencies. When evaluating the long-term safety of FRP tanks, we should check whether the relevant safety system is sound, whether the personnel have received professional training, and whether the emergency response measures for accidents are implemented. Perfect safety management can reduce the impact of human factors on equipment safety and enhance the safety guarantee of overall operation.

Compliance with norms and standards

During the evaluation process, relevant industry standards and national regulations should be referred to, such as "FRP Tank Design Specifications" and "Safety Technical Supervision Regulations for Pressure Vessels". By comparing with the requirements of the specifications, confirm whether the design, manufacture, installation and operation of FRP tanks are in compliance, find non-conformities and make timely rectifications. The implementation of the standard provides technical support and evaluation basis for equipment safety.

Comprehensive evaluation and risk analysis

Combining the above inspections with data, comprehensive evaluation and risk analysis are carried out. By establishing risk level classification, the severity and treatment priority of different problems are clarified. The risk matrix or failure mode effect analysis (FMEA) method is used to quantitatively or qualitatively analyze the factors that may cause tank failure. The comprehensive evaluation results are used to guide management decisions, formulate scientific maintenance plans, and ensure the long-term safe and stable operation of FRP tanks.

Future development direction and challenges of FRP tank technology

Research and development and application of new materials

One of the important development directions of FRP tank technology in the future is the research and development of new composite materials. Traditional FRP tanks mainly use unsaturated polyester resins and glass fibers, but their high temperature resistance, corrosion resistance and mechanical properties have certain limitations.

The introduction of new materials such as high-performance epoxy resins, vinyl ester resins and nano-composites is expected to improve the comprehensive performance of the tank. For example, nanomaterials can improve the structural tightness and toughness of resins, and enhance corrosion resistance and aging resistance. Future research and development will pay more attention to the environmental protection and recyclability of materials to meet the requirements of sustainable development.

Intelligent upgrading of manufacturing process

The improvement of manufacturing process is the key direction for the improvement of FRP tank technology. Traditional hand lay-up and winding processes have problems such as high labor intensity and difficulty in ensuring quality consistency. In the future, automated winding, robot spraying and intelligent monitoring technologies will be more widely used. Automated equipment can accurately control the laying direction and thickness of materials, and improve the uniformity and stability of tank quality. Intelligent manufacturing also includes real-time data collection and analysis during the production process, timely adjustment of process parameters, reduction of defect rate and improvement of production efficiency.

Optimization of structural design

With the diversification of application requirements, the structural design of FRP tanks is also evolving. Future designs will pay more attention to the combination of lightweight and high strength, and optimize the structural layout of the tank through advanced calculation methods such as finite element analysis. The application of multi-layer composite structures and functional gradient materials can realize the customization of the performance of different parts of the tank to meet the needs of different media and working conditions. Modular design and easy-to-maintain structural design will also become a trend, improving the convenience of use and maintenance efficiency of the equipment.

Enhanced adaptability to the use environment

The application environment of FRP tanks is complex and changeable, and future technology will pay more attention to the adaptability of the tank to extreme environments. For example, the improvement of high temperature resistance, low temperature resistance, UV resistance, and freeze-thaw cycle resistance will enable FRP tanks to operate safely in more special occasions. The development of new coating technology and surface treatment technology will help improve the protective performance of the tank and extend its service life.

Advances in quality inspection and monitoring technology

Quality inspection is a key link in ensuring the safe use of FRP tanks. In the future, non-destructive detection technologies will be more advanced, such as acoustic wave detection, infrared thermal imaging, and three-dimensional scanning, which can detect internal defects earlier. The application of online monitoring systems will become a trend. Sensors are used to monitor the stress, temperature, deformation and other states of the tank in real time to achieve early warning. Combined with big data and artificial intelligence technology, an intelligent diagnostic model is established to improve the accuracy and response speed of fault prediction.

Environmental protection and sustainable development needs

With the increasingly stringent environmental regulations, the production and use of FRP tanks must meet higher environmental standards. Future technologies will pay more attention to the green and environmental characteristics of materials, such as the use of low volatile organic compound (VOC) resins and the development of degradable or recyclable composite materials. Energy conservation and emission reduction in the manufacturing process and recycling of waste will also become the focus of technological development.

Expansion of application areas

In the future, the application of FRP tanks will be more diversified, not only limited to traditional chemical storage and water treatment fields, but also expanded to new energy, food and medicine and other industries with higher requirements for material safety and environmental protection. Develop special materials and customized design solutions for different application scenarios to meet the requirements of different media, temperature and pressure. At the same time, combined with intelligent manufacturing and Internet of Things technology, remote monitoring and management of equipment can be achieved to improve operating efficiency and safety.

Technical and market challenges faced

Although FRP tank technology has many development prospects, it also faces certain challenges. The continuous improvement of material performance requires a lot of R&D resources, and the cost and process difficulty of new materials are high. The introduction of manufacturing automation and intelligent equipment requires high capital investment, which puts pressure on small and medium-sized enterprises. The market competition is fierce, and users' requirements for equipment performance and service quality are constantly increasing, prompting enterprises to continue to innovate. The improvement of the standard system and the adaptation of regulations also put forward higher requirements for technological development.

Talent training and technology promotion

Technological progress is inseparable from talent support. In the future, it is necessary to strengthen the training of professional talents in the fields of composite materials, automated manufacturing, and intelligent detection. Enterprises and scientific research institutions should strengthen cooperation to promote the application and promotion of new technologies. Popularizing knowledge related to FRP tanks and improving users' awareness of equipment performance and maintenance are also the key to ensuring safety and performance.

Future Outlook

On the whole, the development of FRP tank technology in the future will focus on new material research and development, intelligent manufacturing and environmental adaptability, and promote the continuous expansion of equipment performance and application scope. In the face of challenges, the industry needs to coordinate technological innovation, cost control and market demand to form a benign development ecology. Through technological progress and management optimization, FRP tanks will play a role in more fields and provide reliable support for industry and environmental protection.

English

English  中文简体

中文简体 Español

Español عربى

عربى русский

русский ไทย

ไทย bahasa Indonesia

bahasa Indonesia Tiếng Việt

Tiếng Việt