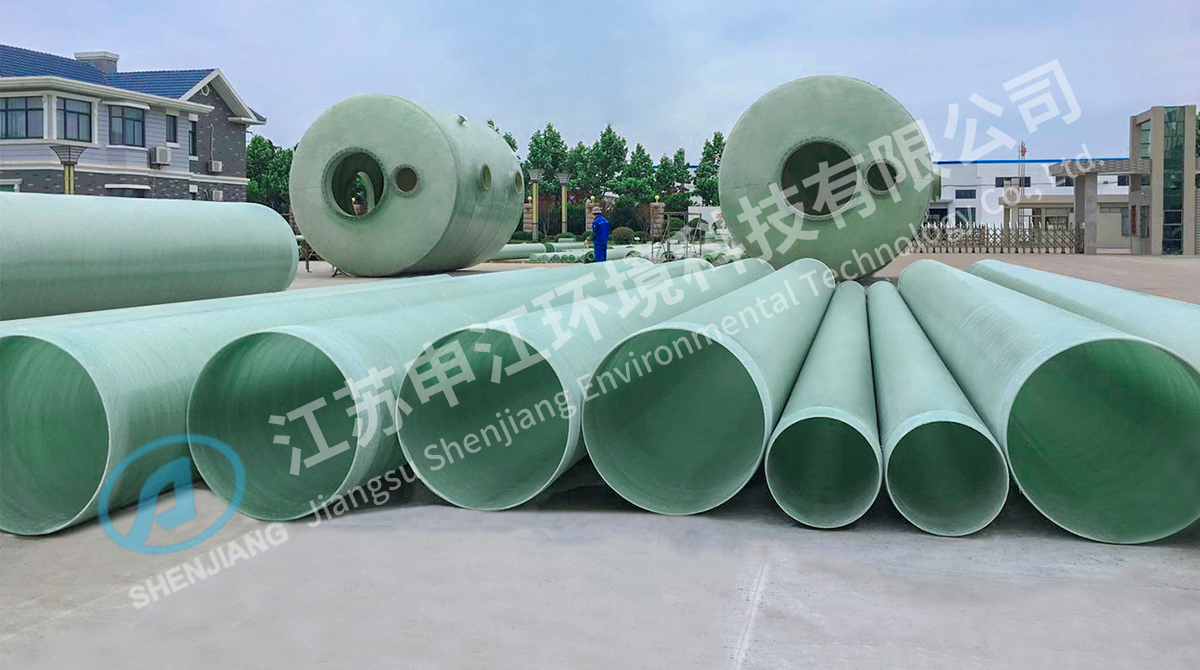

Material Composition

FRP (Fiber Reinforced Plastic) pipes are constructed from a combination of thermosetting resins, such as polyester or epoxy, reinforced with glass fibers. This composition gives them a balance of strength, flexibility, and corrosion resistance. PVC (Polyvinyl Chloride) pipes are made from rigid plastic that offers lightweight properties and chemical resistance but limited strength compared to FRP. Steel pipes are made from carbon or alloy steel, providing high structural strength and pressure resistance but are prone to corrosion unless coated. Concrete pipes consist of cement, aggregates, and reinforcement, offering high compressive strength and durability under heavy loads but being more susceptible to cracking and chemical attack in aggressive environments.

Corrosion Resistance

FRP pipes are highly resistant to corrosion from a variety of chemicals, including acids, alkalis, and saline solutions, due to the protective resin matrix and inert nature of the glass fibers. PVC pipes also resist corrosion from most household and industrial chemicals but may soften or degrade under prolonged exposure to certain solvents or UV light. Steel pipes, unless properly coated or alloyed, are susceptible to rust and corrosion when exposed to moisture or aggressive chemicals. Concrete pipes can experience chemical attack from acidic or sulfate-rich water, leading to degradation over time, although certain protective coatings or liners can improve resistance.

Strength and Mechanical Properties

FRP pipes exhibit a favorable strength-to-weight ratio, allowing them to handle moderate internal pressures and external loads while remaining lightweight for installation. Their flexibility allows them to absorb stresses without cracking. PVC pipes have lower mechanical strength and may require thicker walls or additional supports for high-pressure applications. Steel pipes offer high tensile strength and can handle high pressures and heavy loads but are heavier and require specialized handling. Concrete pipes are strong under compression but relatively weak in tension and bending, requiring careful support during installation to prevent cracking.

Weight and Handling

FRP pipes are lightweight compared to steel and concrete, making transportation, handling, and installation easier and less labor-intensive. PVC pipes are also lightweight and easy to handle, which contributes to faster installation in residential and commercial applications. Steel pipes are significantly heavier, requiring cranes or lifting equipment for handling, particularly in large diameters. Concrete pipes are the heaviest, necessitating specialized equipment for movement and precise placement, which can increase installation time and costs.

Installation and Jointing Methods

FRP pipes can be joined using adhesive bonding, flanged connections, or mechanical couplings, providing flexibility in installation. PVC pipes are commonly joined using solvent welding, gasketed joints, or mechanical couplings, which are straightforward and suitable for lower-pressure systems. Steel pipes are typically welded, flanged, or threaded, requiring skilled labor and equipment for proper assembly. Concrete pipes are usually joined with rubber gaskets or mortar seals and often need cranes for placement due to their weight. The choice of jointing method affects installation speed, labor requirements, and system performance.

Durability and Lifespan

FRP pipes offer a long service life in corrosive environments due to their chemical resistance and resistance to scaling or sediment buildup. PVC pipes can last decades under normal operating conditions but may degrade under prolonged UV exposure or in contact with certain aggressive chemicals. Steel pipes, even when coated or lined, require regular maintenance to prevent corrosion and may have a shorter lifespan in aggressive environments. Concrete pipes are durable under compressive loads and in non-corrosive conditions but can suffer from cracking, spalling, or chemical attack in certain environments, potentially reducing lifespan.

Cost Considerations

FRP pipes typically have a higher initial material cost compared to PVC or concrete pipes but can offer cost savings in corrosive environments due to reduced maintenance and longer service life. PVC pipes are generally the most cost-effective for standard applications with lower pressure and chemical exposure. Steel pipes can be expensive, particularly when corrosion-resistant alloys or coatings are required. Concrete pipes are cost-effective for gravity flow applications and heavy loads but may incur higher handling and installation costs due to their weight and the need for specialized equipment.

Comparative Table of FRP, PVC, Steel, and Concrete Pipes

| Property |

FRP |

PVC |

Steel |

Concrete |

| Material |

Glass fiber reinforced resin |

Polyvinyl chloride |

Carbon or alloy steel |

Cement, aggregates, reinforcement |

| Corrosion Resistance |

High chemical resistance |

Moderate chemical resistance |

Prone to corrosion without coating |

Vulnerable to acidic or sulfate attack |

| Strength |

Good strength-to-weight ratio, flexible |

Lower mechanical strength |

High tensile and pressure strength |

High compressive strength, low tension strength |

| Weight |

Lightweight |

Lightweight |

Heavy |

Very heavy |

| Installation |

Adhesive, flanged, mechanical couplings |

Solvent welding, gasketed joints |

Welding, flanged, threaded |

Gasketed, mortar seals, requires lifting equipment |

| Lifespan |

Long in corrosive environments |

Moderate under normal conditions |

Variable, depends on coating and maintenance |

Durable under compressive loads, affected by chemical attack |

| Cost |

Higher initial cost, lower maintenance |

Low initial cost, cost-effective for light use |

High cost, especially for corrosion-resistant options |

Moderate material cost, higher handling and installation |

Applications and Suitability

FRP pipes are suitable for corrosive fluid transport, industrial chemical handling, and wastewater systems where chemical resistance and long-term performance are essential. PVC pipes are commonly used in residential plumbing, irrigation, and non-aggressive chemical transport. Steel pipes are favored in high-pressure systems, oil and gas pipelines, and structural applications where mechanical strength is critical. Concrete pipes are typically used in gravity sewer systems, drainage, and heavy load-carrying infrastructure, where compressive strength is the primary requirement. Choosing the appropriate pipe type depends on environmental conditions, mechanical requirements, and budget constraints.

English

English  中文简体

中文简体 Español

Español عربى

عربى русский

русский ไทย

ไทย bahasa Indonesia

bahasa Indonesia Tiếng Việt

Tiếng Việt