Understanding Molding Materials in FRP Equipment

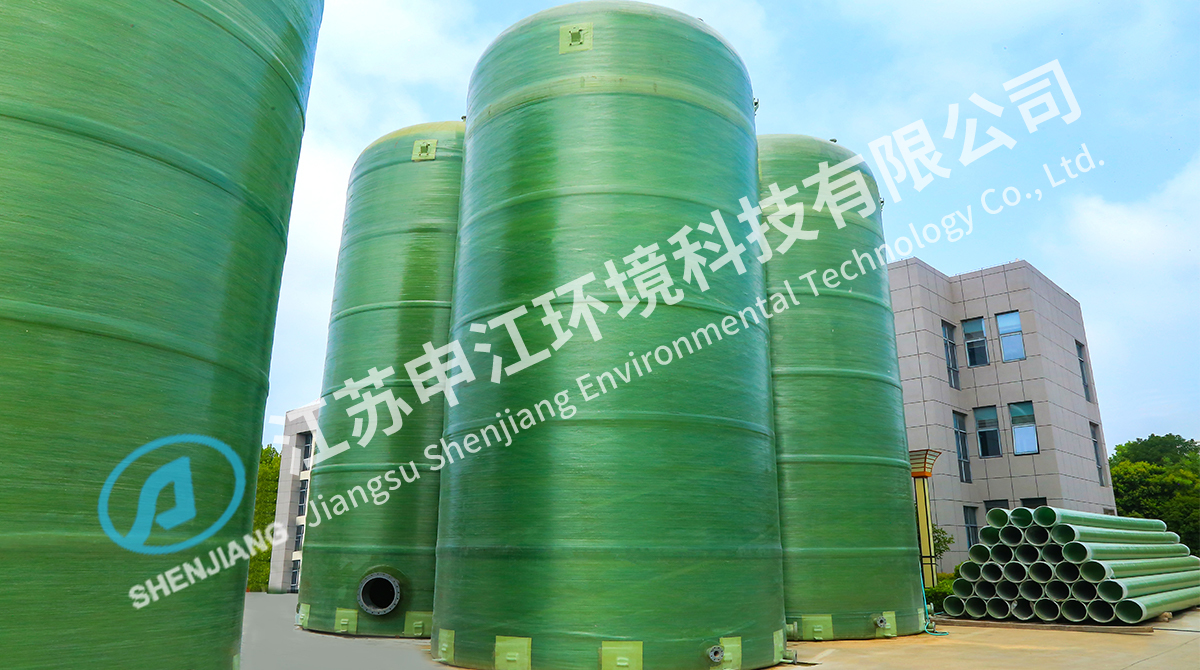

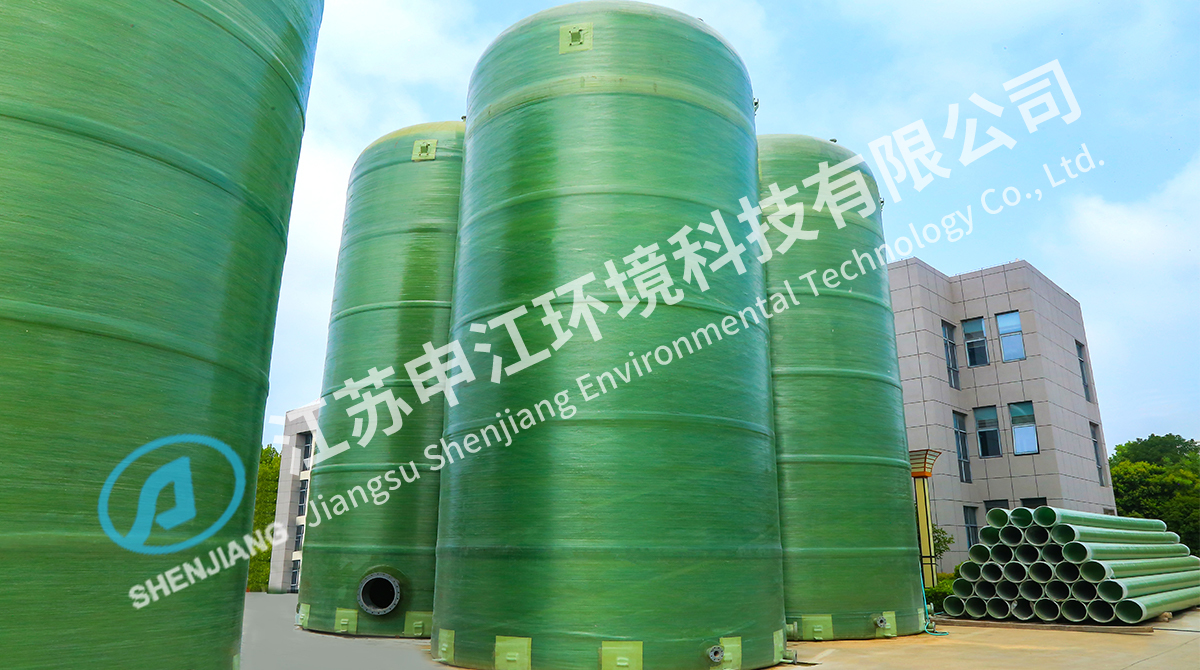

Fiberglass Reinforced Plastic (FRP) is widely used in various industrial applications due to its strength, durability, and resistance to corrosion. FRP equipment, which includes products such as tanks, pipes, and structural components, often relies on molding materials for its production. These materials typically consist of a combination of resins and reinforcing fibers. The most common resins used in FRP molding are polyester, vinyl ester, and epoxy resins, while the reinforcing fibers are primarily made from glass. The choice of molding material is crucial for determining the final performance of FRP equipment, and its environmental impact should not be overlooked. The environmental footprint of these materials, particularly regarding their recyclability and environmental protection requirements, has become an area of growing concern in the manufacturing industry.

Environmental Protection Requirements for Molding Materials

The environmental protection aspect of molding materials for FRP equipment is an increasingly important consideration. As industries become more aware of sustainability, it is necessary to evaluate how the materials used in the production of FRP contribute to environmental protection. In particular, the production and disposal of FRP materials can have significant environmental consequences. The resins used in FRP molding are often derived from petrochemicals, which involve energy-intensive processes and can lead to the release of volatile organic compounds (VOCs) during production. Furthermore, these materials can be difficult to recycle, which results in a large volume of waste at the end of the equipment’s life cycle.

To address these concerns, manufacturers are now focusing on developing more environmentally friendly alternatives. For example, bio-based resins and low-VOC resins are being used as part of efforts to reduce the environmental impact of FRP production. Additionally, the wet process for acid production, often employed in industrial settings, is also being adapted to minimize environmental harm. By using these sustainable materials and processes, the environmental footprint of FRP molding materials can be reduced, contributing to overall environmental protection efforts in the manufacturing industry.

Recyclability of FRP Materials

Recyclability is a significant challenge for FRP materials. Unlike metals and some plastics, which can be easily recycled through established processes, the recycling of FRP is much more complicated. The combination of resin and reinforcing fibers, especially in thermoset resins, makes FRP difficult to break down and reuse. Thermoset resins cure into a rigid structure that cannot be remelted or reformed, making recycling an arduous task. As a result, FRP materials are typically disposed of in landfills or incinerated, which contributes to environmental waste.

However, there have been advancements in the recycling of FRP materials. One of the promising methods is mechanical recycling, where the FRP is shredded and processed into smaller particles that can be used in the production of new materials or as fillers in other industries. Another approach is chemical recycling, which breaks down the resins into their basic components so they can be reused in the production of new resins. Although these recycling methods are not yet widespread, they hold potential for reducing the environmental impact of FRP waste and improving the sustainability of FRP equipment production.

The Challenges of FRP Recycling

The primary challenge in recycling FRP materials lies in the complexity of the composite structure. The resins used in FRP, especially thermosetting resins, form a chemical bond that is not easily reversible, making them resistant to conventional recycling methods. Additionally, the presence of reinforcing fibers like glass complicates the process, as these fibers do not degrade easily and can interfere with the recycling of the resin. Furthermore, the presence of additives and fillers used in the production of FRP equipment can also make recycling more difficult.

Another challenge is the limited infrastructure for FRP recycling. While some progress has been made in developing methods for recycling FRP, the lack of widespread facilities and established processes means that recycling rates for these materials are still relatively low. This situation is further exacerbated by the high cost of recycling FRP compared to traditional waste disposal methods. As a result, many FRP products are discarded without being recycled, leading to an accumulation of waste in landfills.

Alternatives to Traditional FRP Molding Materials

To address both the environmental and recyclability issues associated with traditional FRP molding materials, several alternatives are being explored. One promising alternative is the use of biodegradable resins derived from renewable sources. These resins offer similar performance characteristics to traditional petrochemical-based resins, but they break down more easily when exposed to environmental conditions. Another alternative is the use of natural fibers, such as hemp or jute, as reinforcement in place of glass fibers. These fibers are renewable, biodegradable, and offer a more sustainable option for reinforcing the resin in FRP equipment.

Additionally, thermoplastic resins are being explored as a potential alternative to thermoset resins in FRP molding. Thermoplastics can be re-melted and re-formed, making them easier to recycle and reuse. While thermoplastic FRP is still in the early stages of development, it holds promise for improving the recyclability of FRP products. By integrating these alternative materials into the production of FRP equipment, manufacturers can reduce their environmental impact and enhance the sustainability of the industry.

Environmental Impact of FRP Equipment and Sustainability Initiatives

The environmental impact of FRP equipment extends beyond the molding materials used in their production. In addition to concerns over the recyclability of these materials, the energy consumption during manufacturing and the waste generated during production are significant contributors to the environmental footprint of FRP equipment. To address these issues, many manufacturers are adopting sustainability initiatives that aim to reduce energy use, minimize waste, and lower carbon emissions. For example, the use of energy-efficient equipment, renewable energy sources, and cleaner production techniques is becoming more common in the FRP manufacturing sector.

Furthermore, the design of FRP equipment is also being adjusted to improve sustainability. Designers are increasingly focusing on creating products that are easier to disassemble and recycle at the end of their lifecycle. This includes using modular designs and materials that can be easily separated for recycling or reuse. By adopting these practices, manufacturers can contribute to a circular economy where materials are continually reused and waste is minimized.

Comparison of Environmental Aspects of FRP Molding Materials

| Material Type |

Environmental Protection Impact |

Recyclability |

Challenges |

Potential Alternatives |

| Polyester Resin (Common in FRP) |

High energy consumption, VOC emissions during production |

Low; difficult to recycle due to thermosetting nature |

Limited recycling infrastructure, non-biodegradable |

Bio-based resins, thermoplastic alternatives |

| Vinyl Ester Resin |

Lower VOC emissions, but still based on petrochemicals |

Low; challenging to recycle |

High cost of disposal, difficult to break down |

Natural fiber reinforcements, biodegradable resins |

| Epoxy Resin |

Good chemical resistance but petrochemical-based |

Very low; thermosetting, non-recyclable |

Non-recyclability, disposal challenges |

Natural fibers, renewable resins, chemical recycling |

Future Outlook and Innovations in FRP Manufacturing

The future of FRP equipment and its molding materials looks promising as the industry moves toward more sustainable practices. Advances in materials science are opening up new possibilities for reducing the environmental impact of FRP. As bio-based resins, natural fibers, and recyclable thermoplastic options become more widely available, the production of FRP equipment will become increasingly eco-friendly. Manufacturers are also focusing on developing better recycling methods and improving the efficiency of production processes to minimize waste and energy use.

Continued innovation in the area of FRP materials and manufacturing techniques will be essential for achieving the sustainability goals set by industries worldwide. By investing in research and development, companies can create more environmentally friendly FRP equipment and contribute to the global effort of reducing environmental footprints.

English

English  中文简体

中文简体 Español

Español عربى

عربى русский

русский ไทย

ไทย bahasa Indonesia

bahasa Indonesia Tiếng Việt

Tiếng Việt