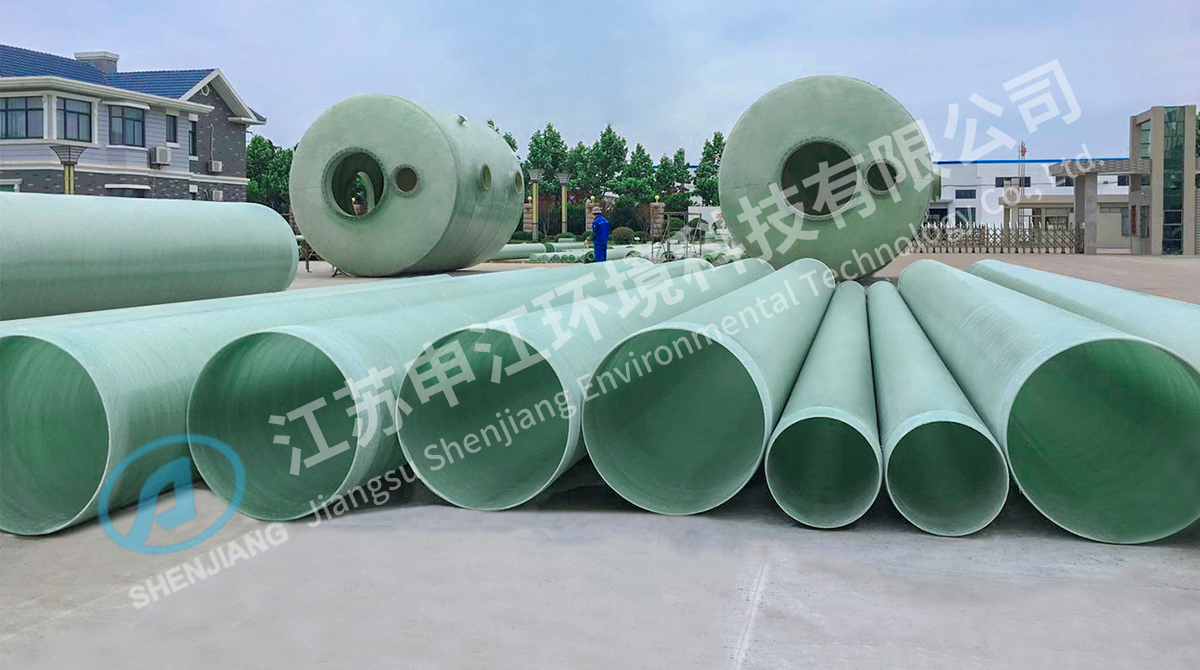

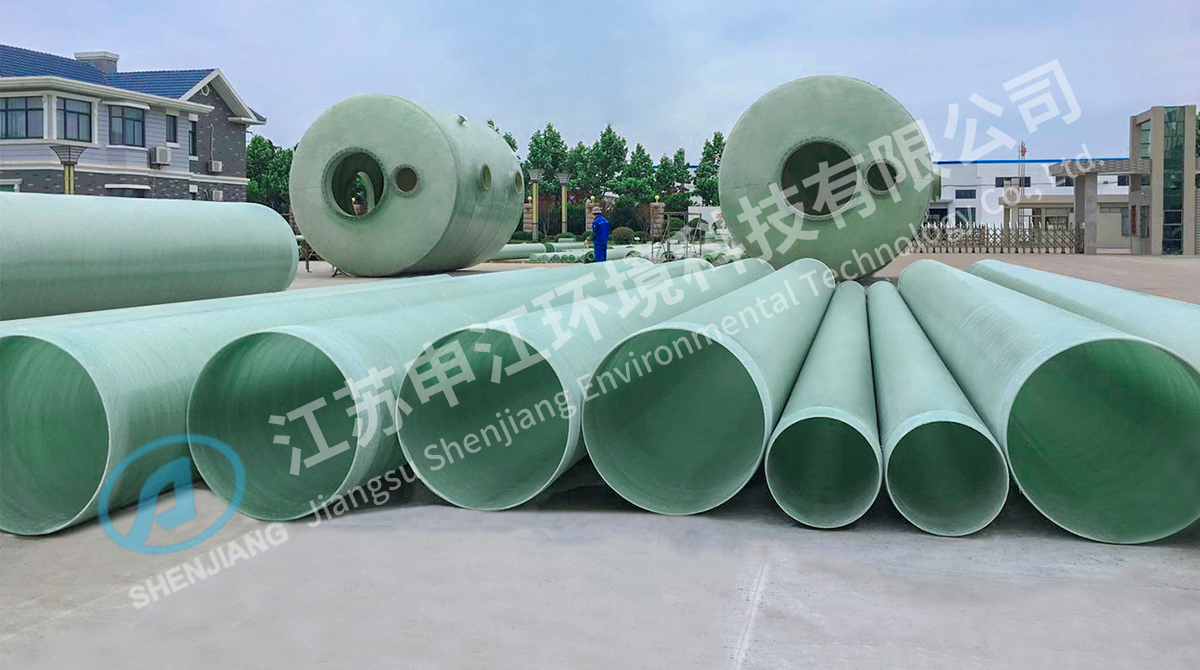

Introduction to FRP Pipes and Fittings

FRP (Fiber Reinforced Plastic) pipes and fittings are composite materials typically composed of a polymer matrix reinforced with glass, carbon, or aramid fibers. They are widely used in industrial, chemical, and water treatment applications due to their corrosion resistance, lightweight nature, and ability to withstand a range of chemical and environmental conditions. FRP pipes combine the flexibility of plastics with the strength of fibers, providing a versatile solution where metals may be susceptible to corrosion or chemical attack.

The structure of FRP pipes and fittings allows for high adaptability in different installations, including pressure pipelines, chemical transfer systems, and infrastructure projects. Despite these advantages, concerns about long-term performance, including brittleness, aging, or cracking, are commonly raised by engineers, designers, and end-users. Understanding these behaviors requires analyzing the material properties, manufacturing methods, environmental factors, and operational conditions.

Material Composition and Its Influence on Longevity

The primary constituents of FRP pipes—resin and fibers—determine their mechanical and chemical stability. Common resins include polyester, vinyl ester, and epoxy, each offering different levels of chemical resistance, tensile strength, and thermal performance. Fibers, usually glass fibers, provide structural reinforcement, enhancing load-bearing capacity and dimensional stability.

The interaction between the resin and fiber network plays a critical role in resisting long-term degradation. A well-bonded fiber-matrix interface distributes stresses throughout the material, reducing the likelihood of localized cracking. Conversely, any imperfection in the resin or inadequate fiber wetting during manufacturing may create weak points, which could become more pronounced over extended periods of service.

Environmental Factors Affecting FRP Performance

FRP pipes and fittings are exposed to a variety of environmental conditions that influence aging and mechanical performance. Factors such as ultraviolet (UV) radiation, temperature fluctuations, humidity, and exposure to chemicals can gradually alter the polymer matrix.

UV radiation can degrade certain resins, particularly polyester, leading to surface embrittlement or chalking over time. Temperature extremes may cause expansion and contraction cycles, stressing the fiber-resin interface. Chemical exposure, depending on the resin type, may lead to slight matrix softening or swelling, though well-selected resins typically resist the chemicals they are intended to handle.

Humidity and water exposure can also affect long-term stability. Water absorption is usually minimal in properly manufactured FRP, but prolonged exposure to aggressive environments may accelerate resin degradation if the resin type is not suitable for the application.

Manufacturing Quality and Long-Term Reliability

The production process of FRP pipes significantly influences their durability. Common manufacturing methods include filament winding, hand lay-up, and pultrusion. Filament winding allows for precise fiber alignment and uniform resin distribution, improving mechanical consistency and reducing the likelihood of voids that can act as stress concentrators.

Hand lay-up techniques may result in slight inconsistencies in fiber placement or resin saturation, which could potentially reduce long-term reliability. Pultrusion, widely used for fittings and smaller-diameter pipes, produces continuous profiles with controlled fiber content and resin distribution, enhancing uniformity and structural integrity.

Mechanical Stress and Fatigue Considerations

FRP pipes are subject to both internal pressure and external mechanical loads during operation. Repeated cycles of pressure or vibration can lead to fatigue over time. The fiber reinforcement provides resistance to crack propagation, but localized defects or areas of stress concentration can eventually develop micro-cracks if the material is not designed to handle operational stresses adequately.

Temperature cycles and pressure fluctuations are particularly relevant in chemical and industrial applications. Fatigue performance depends on fiber orientation, resin type, and wall thickness, with proper design reducing the likelihood of long-term cracking.

Signs of Aging and Brittleness

Over extended periods, FRP pipes may exhibit certain signs of aging. These include surface chalking due to UV exposure, slight discoloration, minor micro-cracking at stress points, and a gradual increase in stiffness. Brittleness may develop primarily in the resin-rich areas or in fibers that have lost adhesion to the matrix due to environmental or chemical attack.

However, most FRP materials are engineered to delay these effects for decades, and observable aging often occurs long after the expected service life. Preventive measures, such as UV inhibitors, chemical-resistant coatings, and proper selection of resin-fiber combinations, contribute to mitigating these risks.

Maintenance and Inspection Practices

Regular inspection is essential for ensuring long-term performance of FRP pipes and fittings. Visual inspections can identify surface cracks, delamination, or discoloration. Non-destructive testing methods, such as ultrasonic inspection or acoustic emission monitoring, provide a deeper understanding of internal structural integrity.

Maintenance practices, including cleaning and monitoring for chemical exposure beyond design limits, help prevent premature aging. Installing supports to minimize excessive bending or vibration further enhances longevity. Well-maintained FRP systems can operate efficiently for decades without significant embrittlement or cracking.

Performance Comparison with Other Materials

Compared to metals, FRP pipes are less susceptible to corrosion but may respond differently under mechanical stress. Metals may deform plastically under high loads, while FRP behaves in a more brittle manner when overloaded. Selecting appropriate wall thickness, fiber orientation, and resin type ensures that FRP pipelines achieve the required mechanical performance without excessive brittleness.

In chemical applications, FRP often outperforms steel and ductile iron in terms of chemical resistance. Table below summarizes typical performance differences in key areas:

| Property |

FRP Pipes |

Steel Pipes |

Polyvinyl Chloride (PVC) Pipes |

| Corrosion Resistance |

High |

Moderate |

High (limited chemical resistance) |

| UV Resistance |

Moderate to high (with additives) |

Low |

Low |

| Mechanical Fatigue Resistance |

Good (fiber-reinforced) |

High |

Moderate |

| Service Life |

20–50 years (depending on conditions) |

15–40 years |

25–40 years |

Design Strategies to Mitigate Aging and Cracking

Engineering considerations can significantly reduce the risk of brittleness or cracking. Choosing the correct resin type for the operational environment, optimizing fiber content and orientation, and incorporating protective coatings all contribute to improved durability. Design standards and guidelines for FRP pipelines provide recommended wall thickness, support spacing, and joint configurations to minimize stress concentrations.

Additionally, installing expansion joints or flexible couplings helps absorb thermal expansion or vibration, reducing the likelihood of long-term material fatigue. By following these principles, FRP pipes can maintain functional integrity for extended periods, even in demanding applications.

Long-Term Performance

FRP pipes and fittings are engineered to withstand a wide range of operational and environmental conditions. While all materials experience aging over time, properly manufactured and installed FRP systems generally resist brittleness, cracking, and premature degradation. Longevity depends on careful selection of resin and fiber type, adherence to design standards, regular inspection, and preventive maintenance. Through thoughtful engineering and application-specific design, FRP pipelines continue to be a reliable solution for industrial, chemical, and water treatment uses over decades of service.

English

English  中文简体

中文简体 Español

Español عربى

عربى русский

русский ไทย

ไทย bahasa Indonesia

bahasa Indonesia Tiếng Việt

Tiếng Việt